Removing and installing a car wheel is not such a rare operation. At least twice a year, every car owner necessarily faces the need to change the seasonal tires. And this means that at least twice a year, you have to remove and put on all four wheels on your car. Some car owners, especially those who have replacement rubber stored together with disks, perform this operation themselves. Also, the need to remove the wheel may arise on the highway when installing a spare tire, when buying new disks and in some other cases.

The instructions indicate that each nut must be tightened with a certain amount of force. Different values are specified for different cars.

So how to correctly calculate the nut tightening torque, and what is fraught with the wrong force of tightening the nuts on the wheel?

The consequences of tightening wheel nuts with the wrong force

Often motorists try to tighten the nuts with maximum force and, not having calculated the force, get sad results. Overtightening of hub nuts leads to unpleasant consequences in the form of broken threads, deformation of hub bolts, and on cars equipped with alloy wheels, to burst disks. Overtightened nuts will almost certainly cause the wheel disk to stick to the hub, and to change such a wheel in case of need will not be so easy. Not to mention that if the nuts are tightened too much, the wheel may come off with the mounting bolts when driving.

Many people mistakenly believe that overtighten the hub nuts can only be done by athletes-culturists. This is not the case. When the leverage of the wrench is large enough, even a small amount of force can tear off the thread on the mounting bolt. We know a case when a fragile girl, installing a spare tire on the track, by turning a long wrench broke in half a steel hub bolt as thick as a finger.

The opposite situation – insufficient bolt tightening – does not bode well for your car either. If the mounting nuts on the wheel will be tightened with insufficient force, they can spontaneously unscrew, and driving with loose nuts on the wheel can not be called safe. Even if the wheel does not fall off at full throttle, when driving with under-tightened nuts, the seat on the disk will be hopelessly broken, and this situation can only be corrected by repairing the disk or replacing it.

Wheel bolt tightening chart for different manufacturers

| Vehicle Manufacturer | Model | Tightening Torque (Nm) | Tightening Torque (ft-lb) |

|---|---|---|---|

| Alfa Romeo | Alfa 145/146/147 | 93 ± 10 | 68 ± 5 |

| Alfa Romeo | Alfa 156 | 98 | 72 |

| Alfa Romeo | Alfa 159 | 120 ± 12 | 88 ± 10 |

| Alfa Romeo | Alfa 16 | 86 ± 8 | 65 ± 5 |

| Alfa Romeo | Alfa Brera/Spider/Giulia/Giulietta/Stelvio | 120 ± 12 | 88 ± 8 |

| Audi | A1/A2/A3/A4/A5/A6/A7/A8/TT | 120 | 88 |

| Audi | Q3/Q5 | 140 | 103 |

| Audi | Q7 | 160 | 118 |

| BMW | 1 series/2 series/3 series/4 series/5 series/7 series | 120 | 88 |

| BMW | M2/M3/M4/M5 | 120 | 88 |

| BMW | Z3/Z4 | 100 ± 10 | 73 ± 7 |

| BMW | X1/X2/X3/X4/X5/X6 | 140 | 103 |

| Chevrolet | Cruze/Malibu | 140 | 103 |

| Chevrolet | Captiva | 125 | 92 |

| Chevrolet | Spark | 120 | 88 |

| Chrysler | 300C | 150 | 110 |

| Chrysler | 200C | 120 | 88 |

| Chrysler | Grand Voyager | 135 | 100 |

| Citroen | Xsara Picasso/Saxo | 85 | 62 |

| Citroen | C4/C5 | 80-100 | 59-75 |

| Citroen | Verlingo | 85 | 62 |

| Citroen | AX10/AX11/AX14/Sport | 90 | 65 |

| Ford | Bronco/Ranger/Maverick/Edge/Explorer/Escape | 135 | 100 |

| Ford | F150/F250 | 135-200 | 100-150 |

| Ford | KA/Mondeo/Scogrio/Pumaa/Ecosport | 85 | 62 |

| Ford | Cougar | 128 | 95 |

| Ford | Fiesta | 90 | 67 |

| Ford | Fiesta/Focus/Kuga | 110 | 82 |

| Ford | Fusion | 110 | 82 |

| Ford | Probe | 90-120 | 65-90 |

| Ford | Transit connect | 90 | 65 |

| Fiat | 500/600 | 86 | 63 |

| Fiat | Grande Punto/Punto Evo | 120 | 88 |

| Fiat | Ducato/Talento | 160 | 118 |

| Fiat | Ducato Maxi | 180 | 132 |

| Hyundai | Sonata/Elantra/i10/i20/i30/i40 | 110 | 82 |

| Hyundai | Starex/Santa Fe/Santa Cruz/Kona/Ioniq/Tucson | 130 | 96 |

| Honda | All models | 108-110 | 81 |

| Jeep | Cherokee | 136 | 100 |

| Jeep | Compass | 135 | 99 |

| Jeep | Patriot/Wrangler | 135 | 99 |

| Jaguar | XKR | 125 | 92 |

| Jaguar | S-Type | 128 | 94 |

| Jaguar | XJ6 | 68-85 | 50-62 |

| Jaguar | XJR/XJ12 | 88-102 | 65-75 |

| Jaguar | XJ8/XJ-S | 66-82 | 48-60 |

| KIA | Sorento/Picanto | 100 | 74 |

| KIA | Rio/Ceed/Cerato | 103 | 76 |

| KIA | Carnival | 100 | 74 |

| KIA | Margentis | 98 | 72 |

| Lada | Samara/Riva | 70-78 | 52-57 |

| Lada | Niva | 88-91 | 65-67 |

| Land Rover | Freelander | 133 | 98 |

| Land Rover | Discovery/Range Rover | 140 | 103 |

| Mercedes-Benz | A/SLK/CLK/CLS | 110 | 82 |

| Mercedes-Benz | B/C/E | 103 | 76 |

| Mercedes-Benz | S/M/G/GLC/GLE/GLK/GL | 150 | 110 |

| Mini | Mini/Countryman/Clubman | 140 | 103 |

| Mitsubishi | Colt/Almara/Cube/Serena | 108 | 79 |

| Mitsubishi | Lancer/Grandis/Outlander | 98 | 72 |

| Nissan | Micra/Note | 105 | 77 |

| Nissan | Teana/Altima | 110 | 81 |

| Nissan | Patrol/Terrano/Qashqai/Titan | 133 | 98 |

| Opel | Frontera | 118 | 87 |

| Opel | Astra | 140 | 103 |

| Opel | Insignia | 150 | 110 |

| Opel | Other models | 110 | 81 |

| Porsche | All models | 130 | 95 |

| Peugeot | 106/107 | 85 | 62 |

| Peugeot | 108/208/308/408/508/1008/2008/3008/4008/5008/207/407/807 | 100 | 73 |

| Peugeot | 307/607 | 90 | 66 |

| Renault | Austral/Arkana/Captur/Clio/Twingo/Twizy/Zoe | 105 | 77 |

| Renault | Megan/Scenic/Kadjar | 110 | 81 |

| Renault | Laguna/Latitude/Espace | 130 | 95 |

| Seat | Ibiza/Toledo/Leon | 120 | 88 |

| Seat | Alhambra | 140 | 103 |

| Skoda | Fabia/Octavia/SuperB/Yeti/Karoq/Kamiq/Kodiaq | 120 | 88 |

| Suzuki | Swift/Spash | 85 | 62 |

| Suzuki | Grand Vitara | 100 | 73 |

| Volvo | XC9O/XC6O/XC7O/S60/S80 | 140 | 103 |

| Volvo | XC60/C70/S40 | 110 | 81 |

| Volkswagen | Polo/Golf/Jetta/Passat/T-Roc | 120 | 88 |

| Volkswagen | Sharan | 170 | 125 |

| Volkswagen | Toureg | 180 | 132 |

| Toyota | Avensis/Camry/Corolla/Yaris | 103 | 75 |

| Toyota | Land Cruiser/Tundra | 140 | 103 |

How to properly tighten wheel bolts and nuts

The tightening force of fasteners for each make and model of car is specified in the official instructions from the manufacturer. The parameter varies in the range of 80-200 Nm, so it is necessary to take into account the factory recommendations.

The use of a conventional wrench is undesirable, since in most cases the tightening torque in this case is exceeded. This is especially true for wrenches with telescopic handle, which increase the tightening force.

To tighten the nuts with the required force, use a torque wrench. On this tool you need to set the required value according to the manufacturer’s table, and then fix the fastener. Actions with a torque wrench do not require special skills. Especially convenient in the work of tools with a limiter. Such models simply stop working when the set value is reached.

If you do not have a torque wrench, you can use a pneumatic wrench. This tool allows you to manually adjust the tightening process.

How to properly tighten fasteners:

- Put the wheel on the studs or special guides.

- Tighten the bolts with the necessary force so that the wheel does not come off.

- Use a tool to tighten the nuts to the correct torque.

Modern aluminum nuts are particularly sensitive to tightening requirements. They are not subject to corrosion and last longer, but require strict adherence to the specified tightening torque parameters.

Fastener Tightening Schemes

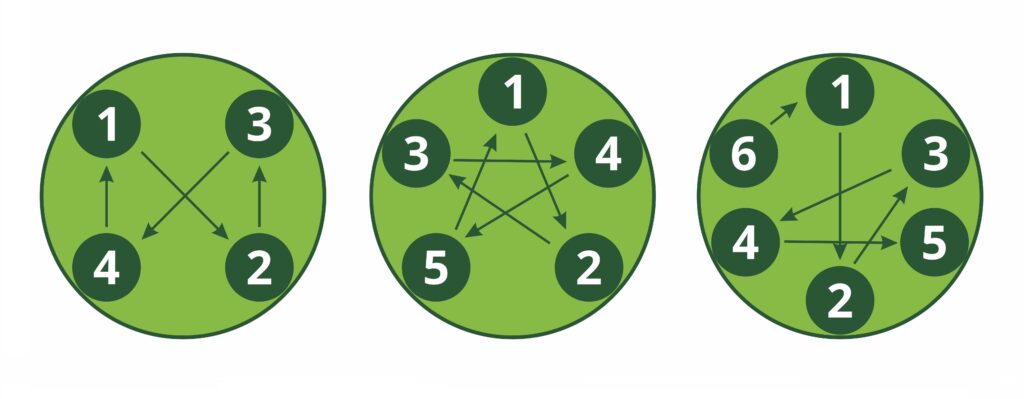

For tightening the wheel, special schemes are used, indicating the sequence of tightening the bolts. For 4 pieces it is 1-3-4-2, for 5 bolts 1-4-2-5-3. The sequence is extremely important so that the forces are distributed evenly. If you don’t follow the rules, the wheel may skew when secured.

When tightening, it is important not to be tempted to tighten the bolts in a clockwise direction. You can start with any bolt, counting from it. Some car owners put special marks on the fasteners so that nothing can be confused.

Sometimes the cause of runout in the suspension is not a weak tightening, but an incorrect selection of fasteners. It is not about the diameter (bolts of a different cross-section to put physically impossible), but about the shape of the bolt head. It can be cone-shaped, spherical, press washer type and so on. The manufacturer’s requirements for the type of fasteners must be observed. In addition, the nuts must perfectly fit the disks and the wheel in length.

Tools for proper tightening

In numerous vehicle operating instructions, manufacturers specify only basic rules for how to properly tighten the bolts on the wheels. Specialists of specialized service centers strongly recommend familiarizing yourself with them in order to avoid consequences. In addition, it is required to know:

- The appropriate torque for tightening wheel bolts differs among themselves and depends on the type of vehicle used;

- To organize effective tightening, it is required to have a specialized torque wrench. It is a specialized device, the functionality of which allows you to set the appropriate torque.

- After the required torque has been set, vehicle owners do not have to worry about a properly tightened wheel experiencing overload. When the required tightening torque is successfully achieved, the wrench automatically turns, eliminating the consequences.

- Car service experts do not recommend tightening without measuring, which is associated with high risks. For example, insufficient tightening of the front wheels entails a jerking of the steering wheel during the movement of the vehicle, including runout.

- When the rear axle is loosely torqued, there are risks of run-out, increased wear of tires and steering rods, bearing failure, pronounced deformation of the disk.

Compliance with clear instructions guarantees a positive result. The procedure is not complicated and is available to all motorists.